PRESSURE VESSEL FABRICATION

We are engaged in offering Pressure Vessel Manufacturing Work to our clients. Our range of all products is widely appreciated by our clients

ENGINEERING STRUCTURE FABRICATION

We will provide the all types of structural fabrication and Erection service with good quality and productivity.

BLOWER BLADE

INDUSTRIAL CENTRIFUGAL BLOWER

Centrifugal Blowers are also known as Centrifugal Fans. The kinetic energy produced by the

impellers of the Centrifugal Blower Fan on rotation is used to increase the pressure of the air

stream, which in turn moves them against the resistance caused, by ducts, dampers and other

components.

MACHINERY FABRICATION

STEEL FABRICATION

Steel fabrication is one of the core services offered by Infinity Engineering, involving the transformation of raw steel into a wide range of structures and components used in various industries. The process requires precision, expertise, and the use of advanced tools and technologies to ensure that the fabricated steel meets the specific needs of each project.

Design & Planning: Developing accurate blueprints and fabrication drawings. Material

Selection: Choosing suitable grades of steel or metal based on structural requirements.

Quality Control: Thorough inspection to meet strength, safety, and specification standards.

Design & Planning: Developing accurate blueprints and fabrication drawings. Material

Selection: Choosing suitable grades of steel or metal based on structural requirements.

Industrial Plants

Structural analysis and engineering calculations to ensure safety and efficiency.

Design & Planning: Developing accurate blueprints and fabrication drawings. Material

Selection: Choosing suitable grades of steel or metal based on structuralrequirements.

Quality Control: Thorough inspection to meet strength, safety, and specification standards.

Surface Treatment: Applying protective coatings to ensure durability and corrosion resistance.

Selection: Choosing suitable grades of steel or metal based on structural requirements.

Engineering structure fabrication involves creating structural components for buildings,bridges, and other large-scale projects. This process includes several key steps:

Heavy and light structural steel fabrication

Customized design and fabrication projects

Selection: Choosing suitable grades of steel or metal based on structural

requirements.

Design & Planning: Developing accurate blueprints and fabrication drawings. Material

Assembly & Welding: Assembling components and welding them according to engineering standards.

Cutting & Shaping: Using tools like CNC plasma cutters, shears, and press brakes for precision shaping.

Surface Treatment: Applying protective coatings to ensure durability and corrosion resistance.

Quality Control: Thorough inspection to meet strength, safety, and specification standards.

offering comprehensive services that cover the entire process from design to installation. The company is equipped to handle complex projects, including the construction of various industrial facilities such as manufacturing plants, processing plants, and other large-scale industrial structures.

Structural analysis and engineering calculations to ensure safety and efficiency.

Customized plant designs tailored to specific industrial needs.

High-quality fabrication of frameworks, supports, platforms, and other structural elements..

Cutting, drilling, bending, and welding of steel components to create the necessary structures

Use of advanced techniques and equipment to ensure precision and durability.

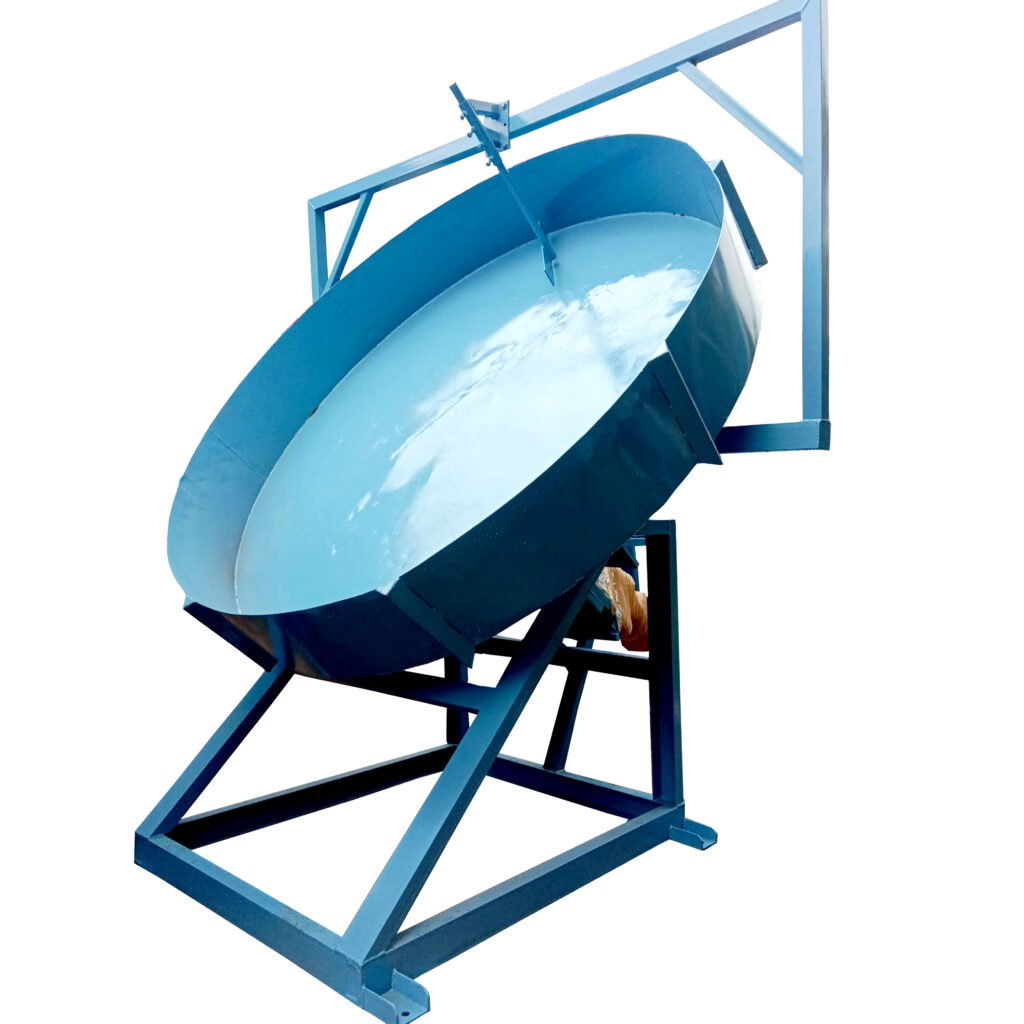

Rotary dryer

THREE ROLLER MILLING MACHINE